Product Description

Innovative Material Composition Design

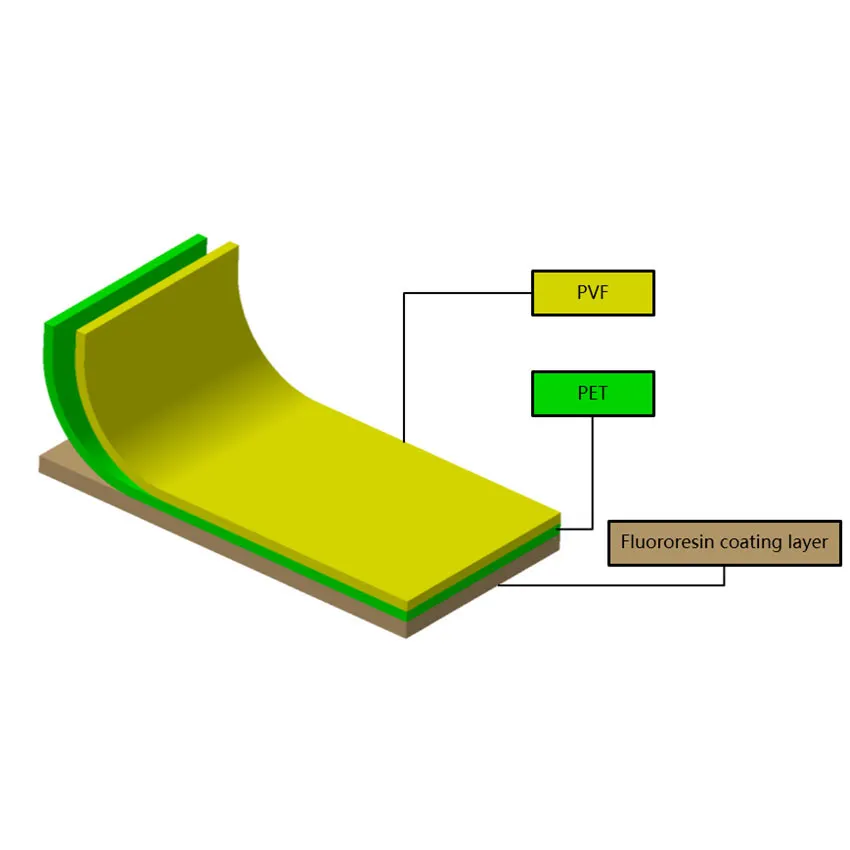

The TPCw1 backsheet features a unique dual-layer composite structure:

1. Weather-resistant layer using DuPont™ transparent Tedlar® film:

- Special polymer formulation with precise thickness control (125±5μm)

- High-efficiency UV stabilizers for long-term weather resistance

- Specially treated surface with self-cleaning functionality

- Complies with ISO 13468 light transmittance testing standard

2. Bonding layer with independently developed fluorinated coating technology:

- Special fluorocarbon resin system forming 3D cross-linked structure

- UV-resistant modifiers to enhance weather durability

- Initial peel strength ≥70N/cm for reliable encapsulation

- Validated by 1000-hour aging test at 85°C/85%RH

Excellent Optical and Environmental Performance

1. Optical characteristics:

- Total light transmittance ≥91.5%, maximizing rear-side power gain

- Haze <2%, ensuring consistent module appearance

- Color difference ΔE<1.5, no discoloration over time

- Light transmittance retention >95% after 3000-hour UV aging

2. Environmental durability:

- Passes 3000-hour damp heat test (85°C/85%RH)

- No abnormalities after 200 thermal cycles (-40°C~85°C)

- Maintains structural integrity after 50 freeze-thaw cycles

- No corrosion after 1000-hour salt spray test

Reliable Module Encapsulation Performance

1. Interface compatibility with EVA:

- Passes 1000-hour compatibility test at 85°C/85%RH

- Interface bonding strength >60N/cm for long-term reliability

- Bubble area <0.5%, minimizing optical loss

- Yellowing index ΔYI<2, maintaining aesthetic appeal

2. Long-term operation assurance:

- UV aging resistance >120kWh/m², exceeding industry standards

- Passes hot spot test at 150°C local high temperature

- Excellent anti-PID performance for high-efficiency modules

- Certified to IEC 62788-7-2 and other international standards

Strict Quality Control System

Each production batch undergoes:

Comprehensive raw material inspection

Real-time monitoring of key production parameters

100% finished product appearance and optical performance inspection

Regular sampling for accelerated aging tests

Complete quality traceability records

Wide Range of Applications

Particularly suitable for:

Utility-scale bifacial power plants

Commercial and industrial bifacial module projects

BIPV building-integrated applications

PV installations in high-reflectivity environments

Special applications like agrivoltaics

Lucky remains committed to optimizing the performance of TPCw1 transparent backsheet products to provide superior solutions for bifacial module technology development. We cordially invite industry partners to visit our R&D center and production facilities to jointly explore innovations and applications in bifacial power generation technology.