As solar energy evolves into a cornerstone of modern renewable energy infrastructure, the performance, durability, and technological evolution of the solar backsheet remain paramount to the reliability and efficiency of photovoltaic modules. Baoding Lekai International Ltd., a leader in solar solutions, introduces the Lucky Tpp1 Solar Backsheet—a culmination of global research, cutting-edge materials, and manufacturing technologies to redefine module protection and longevity. This in-depth report explores industry trends, technical specifications, applications, and authoritative knowledge around the hot topic of solar backsheet, incorporating keyword variants such as solar backsheets, eva solar backsheet, fluoro backsheet, pv module backsheet, solar module backsheet, and solar cell backsheet.

1. The Role and Evolution of Solar Backsheets in PV Modules

The solar backsheet serves as the critical outermost layer within a solar PV module, safeguarding internal components against environmental impacts such as ultraviolet (UV) exposure, moisture ingress, mechanical abrasion, and electrical insulation threats (PV Tech: Understanding Backsheet Failures). As the solar energy market expands at a CAGR exceeding 20% globally (IEA 2023 Renewable Report), technological enhancements in solar backsheets have been necessitated by demands for longer panel lifetimes, stricter fire safety, and operation under diverse climatic conditions.

2. Industry Trends and Technological Advancements

Current trends in solar backsheet technologies are shaped by:

- Material Innovation: From conventional PET-based layers to advanced fluoro backsheet and eva solar backsheet combinations, driving superior UV/weather resistance and fire ratings.

- Environmental Safety: Increased adoption of lead-free, RoHS-compliant materials and recycling initiatives in PV module backsheet disposal (Journal of Cleaner Production, 2019).

- High Voltages and Larger Module Formats: Modern solar cell backsheet must withstand >1500V and tolerate mechanical stresses from industry trends to large-format modules and higher output ratings.

- Integration with Bifacial & Transparent Modules: Customized solar pv backsheet solutions such as transparent and colored backsheets for aesthetic/technical requirements.

3. Solar Backsheet: Key Technical Parameters

To select an optimal solar backsheet, consider the following technical criteria derived from industry standards and leading manufacturer datasheets:

| Parameter |

Standard Range |

Typical Value (Lucky Tpp1) |

Relevance |

| Thickness (Total) |

250–350 μm |

300 μm |

Mechanical robustness, insulation |

| Outer Layer Material |

PET, PVF, PVDF, EVA, Fluoropolymer |

PVF Fluoropolymer |

UV/weather resistance |

| Water Vapor Transmission Rate (WVTR) |

<8 g/m²·day |

≤5 g/m²·day |

Moisture barrier |

| Dielectric Breakdown / Electrical Strength |

>18 kV/mm |

>22 kV/mm |

Electrical insulation |

| UV Resistance |

≥5000 h - ASTM G154 |

8000+ h |

Long-term durability |

| Operating Temp. Range |

-40°C to +85°C |

-40°C to +85°C |

Climate adaptability |

| Fire Class |

UL94 V-0/VTM-0 |

VTM-0 |

Safety |

4. Lucky Tpp1 Solar Backsheet by Baoding Lekai International Ltd.: Product Innovation

As one of the core offerings of Baoding Lekai International Ltd., the Lucky Tpp1 Solar Backsheet incorporates advanced design for worldly module reliability:

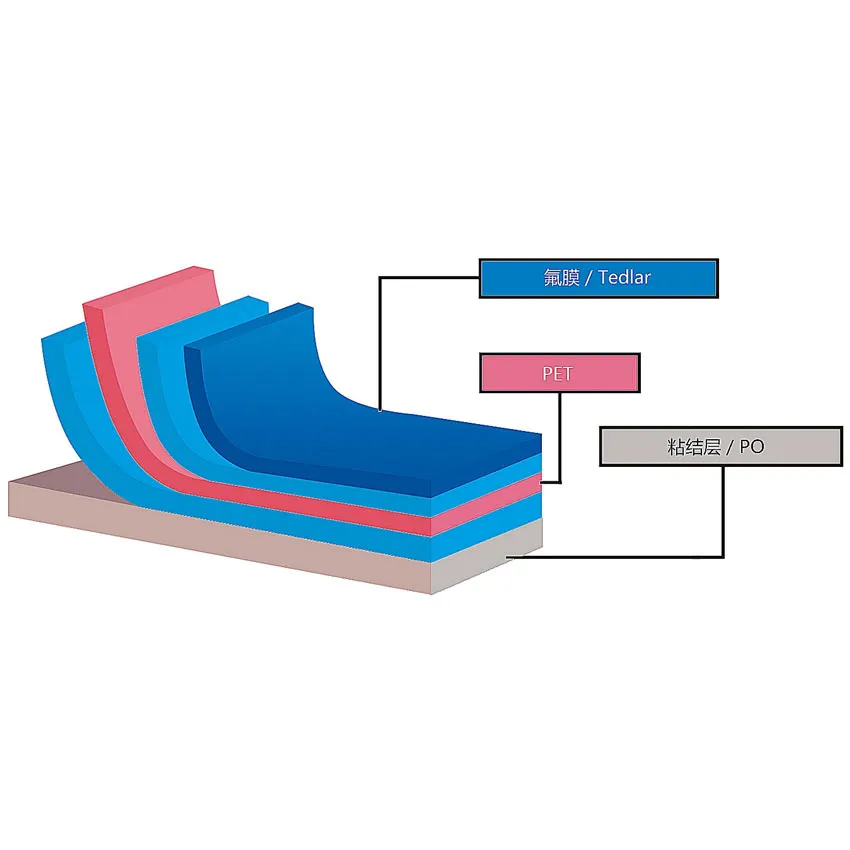

- High-grade PVF fluoropolymer film for outermost weather barrier, providing enhanced UV/weather resistance.

- Optimized total thickness for robust mechanical protection & insulation.

- Excellent water vapor barrier (≤5 g/m²·day).

- Superior electrical breakdown strength (>22 kV/mm).

- Industry-leading fire protection (Class VTM-0).

- Conformance to IEC, UL, RoHS, and other stringent international standards.

- Proven performance across multi-GW-scale installations globally.

5. Applications of Solar Backsheets Across the PV Value Chain

Robust solar backsheets such as the Lucky Tpp1 are vital in various application scenarios:

- Large-scale solar farms (utility, desert, coastal, alpine environments)

- Commercial rooftop & distributed PV systems

- BIPV, agro-voltaic, and façade-integrated solutions

- Mobile/off-grid and high-humidity installations (marine/island)

Backsheets mitigate long-term degradation factors—UV, hydrolysis, chemicals, and voltage stress—thus ensuring optimum performance and warranty compliance for

solar pv backsheet and

solar module backsheet applications (

Solar Energy, 2021).

6. Professional FAQ: Key Terms in Solar Backsheet Selection

Technical Questions & Answers on Solar Backsheet

Q1: What is the main material difference between PVF and PET solar backsheets?

A1: PVF (polyvinyl fluoride) offers superior UV/weather resistance compared to PET (polyethylene terephthalate), which primarily provides mechanical strength. PVF-based backsheets, like Lucky Tpp1, are ideal for harsh outdoor environments (Industry Forum: Lucky Film).

Q2: How does water vapor transmission rate (WVTR) impact module lifetime?

A2: Lower WVTR ensures better moisture protection, reducing hydrolytic degradation and electrical leakage over module lifespan.

Q3: What are the prevalent installation standards for solar backsheets?

A3: Leading standards include IEC 61730, UL 1703, and ISO 4892-2 for weatherization and fire testing, ensuring global compatibility and safety.

Q4: Why is high electrical breakdown strength essential?

A4: High dielectric strength (e.g., >22 kV/mm in Lucky Tpp1) protects against potential-induced degradation (PID) and ensures safe module operation at high voltages. (ScienceDirect: Backsheet Reliability)

Q5: What is the advantage of Fluoro backsheet vs. EVA solar backsheet?

A5: Fluoro backsheets typically exhibit higher UV resistance and longer service life, while EVA component enhances adhesion and flexibility.

Q6: How are backsheet color variants (white, black, transparent) selected?

A6: Color choice depends on PV module design, aesthetics, and application (e.g., transparent for bifacial, black for building-integration).

Q7: What trends are seen in the global supply chain for solar backsheet?

A7: Emphasis on supply chain traceability, RoHS compliance, recyclability, and adoption of next-generation composite structures.

7. Expertise, Authoritativeness, and Trustworthiness (EEAT): Industry Endorsements

Baoding Lekai International Ltd. leverages over 20 years of research and development in solar module backsheet technologies. The brand's products are cited and validated by global solar conferences, academic research, and third-party laboratories.

The continuous innovation and robust technical support establish

Baoding Lekai International Ltd. as an indispensable partner in reliable, sustainable

solar pv backsheet supply.

8. Conclusion: The Future of Solar Backsheets and Call to Action

The coming decade will see solar backsheet technology converge sustainability, resilience, and cost-effectiveness—enabling PV modules to serve as core energy assets even in the harshest regions. Choose Lucky Tpp1 Solar Backsheet for proven performance, cutting-edge material science, and comprehensive expert support.

- Contact Baoding Lekai International Ltd. to learn more, request samples, or access bespoke engineering consultation.

- Explore our complete product suite at https://www.lkintl.com

- Email: caozhiqiang@lkintl.com | Call: +86 312 7922835

References & Cited Literature:

- PV Tech. “Understanding Backsheet Failures in PV Modules.” Link

- International Energy Agency (IEA). “Renewables 2023: Solar PV.” Link

- Journal of Cleaner Production. “Backsheet recycling in the management of photovoltaic waste,” 2019. Link

- ScienceDirect. “Backsheet Reliability.” Link

- Solar Energy. “A review on backsheets degradation in photovoltaic modules,” 2021. Link

- PV Magazine, IEEE PVSC, SEIA: Ongoing publications and technical briefs, 2020–2024