In the ever-evolving photovoltaic (PV) industry, **solar backsheet manufacturer** innovation sits at the forefront of solar panel efficiency, longevity, and safety. As global demand for high-performance renewable energy soars, the need for advanced solar backsheet manufacturer solutions has never been greater. Baoding Lekai International Ltd., a world-renowned name in the field, leads the industry by producing and supplying top-tier backsheet materials designed to optimize PV module performance across diverse climatic and operational scenarios.

Company: Baoding Lekai International Ltd.

Official Website: https://www.lkintl.com

The solar backsheet manufacturer industry is experiencing a macro shift powered by global decarbonization ambitions, increased energy yields, and rapid deployment of solar farms. Projections by key industry forums, such as PV Tech (source), show the global PV installation capacity will surpass 400GW by 2025, with advanced backsheet technologies playing a vital role. As both new installations and module repowering accelerate, market competition among solar backsheet suppliers grows increasingly intense.

Key drivers and trends include:

| Parameter | Typical Value | Industry Standards | Remarks |

|---|---|---|---|

| Thickness (mm) | 0.30 – 0.35 | IEC 61730-2 | Ensures mechanical protection |

| Tensile Strength (MPa) | >120 | ASTM D638 | Essential for durability |

| UV Resistance | ≥ 2,000h | ASTM G154 | Resists degradation outdoors |

| Water Vapor Transmission Rate (WVTR, g/m²·day) | < 2.5 | ASTM E96 | Electrical safety & performance |

| Adhesion Strength (N/cm) | > 5.0 | IEC 62788-1-4 | Layer integrity |

| Operating Temperature Range (°C) | -40 to 85 | IEC 61215 | Climatic adaptability |

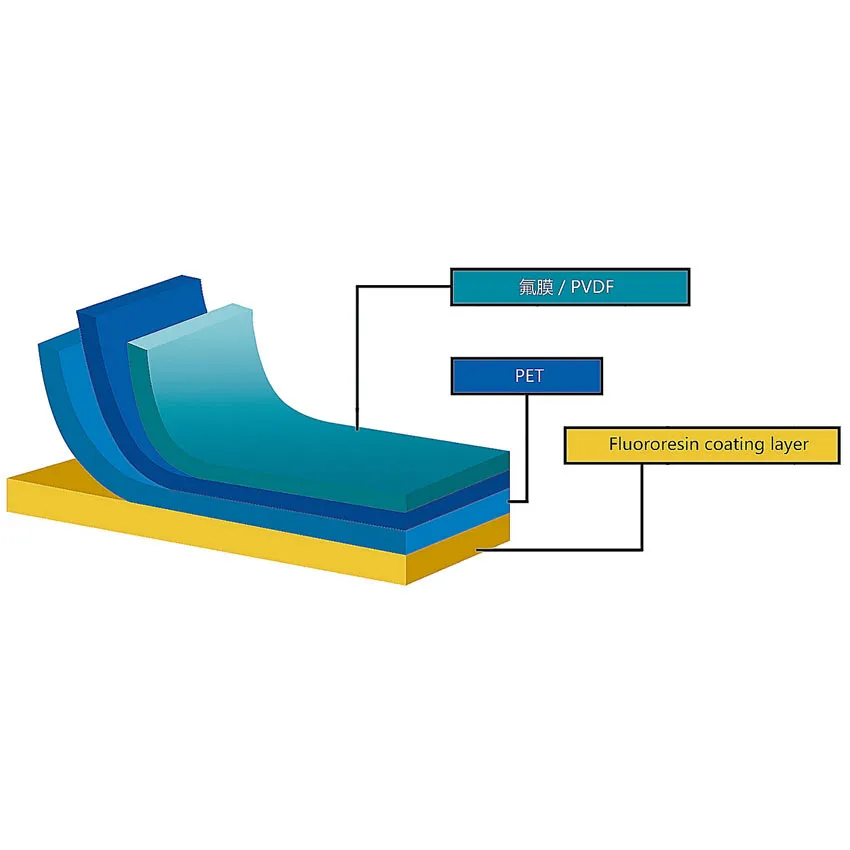

When it comes to industry-leading solar backsheet manufacturer offerings, the Lucky Kpcw1 Solar Backsheet by Baoding Lekai International Ltd. is truly outstanding. It is celebrated for exceptional environmental resistance, top-tier performance, and longevity. Its advanced PVDF fluoropolymer weather-resistant layer offers robust protection against environmental hazards — an aspect heavily cited in PV module durability discussions (Renewable and Sustainable Energy Reviews).

Product URL: https://www.lkintl.com/lucky-kpcw1-solar-backsheet.html

| Specification | Lucky Kpcw1 Value | Industry Average | Remarks |

|---|---|---|---|

| Material Type | PVDF/ PET/ PET | PET, Tedlar/PET/EVA | Superior environmental durability |

| Thickness (mm) | 0.32 ± 0.02 | 0.30 | Consistent mechanical protection |

| Tensile Strength (MD/TD) (MPa) | ≥ 140 / ≥ 125 | 120 / 110 | High strength, long lifespan |

| Elongation at Break (%) | ≥ 90 | ≥ 80 | Flexibility in installation |

| WVTR (g/m²·day) | ≤ 1.5 | 2.4 | Enhanced electrical insulation |

| Peel Strength (N/cm) | ≥ 7.0 | 5.0 | Secure multi-layer integrity |

| Surface Color | White | White, Black | Promotes albedo, module efficiency |

| Exposure Resistance | ≥ 2000h (QUV) | 1500h | Superior outdoor endurance |

The material composition and structure significantly determine a backsheet’s suitability to various application scenarios, from utility-scale solar farms to residential rooftop PV systems. Key types of solar backsheet structures include:

As solar power cements its role in global energy transformation, backsheet innovation will remain a core driver for module performance, safety, and installation returns (Nano Energy Journal). By sourcing from a reputable and technologically advanced **solar backsheet manufacturer** like Baoding Lekai International Ltd., EPC contractors, project developers, and OEMs gain not only product assurance but also professional technical support at every stage of their PV deployment.

From advanced fluoropolymer to hybrid solar backsheet material blends, and from solar backsheet film innovations to emerging circular recycling models (as discussed in PV Education), the future offers huge opportunities for collaborative value creation.

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Lucky Group Official Announcement: Classic Black & White Film Relaunch – A Tribute To The Analog Era

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.