Solar backsheets are the critical protective layer in photovoltaic modules, shielding solar panels from environmental degradation while ensuring long-term electrical insulation. As the global PV market expands to 1.2 TW by 2025 (IEA Report), the demand for high-performance solar backsheet film materials grows exponentially. This guide examines industry-leading solar backsheet suppliers, material innovations, and technical specifications essential for optimizing PV module longevity.

Explore Premium Backsheet SolutionsThe global solar backsheets market will reach $4.3 billion by 2028, growing at 12.5% CAGR (Grand View Research). Major developments include:

| Parameter | Standard | Fluoropolymer | Coated PET | CPCW Composite |

|---|---|---|---|---|

| UV Resistance (kWh/m²) | IEC 61215 | ≥300 | 200-250 | ≥400 |

| Dielectric Strength (kV/mm) | UL 94 V-0 | ≥30 | ≥25 | ≥35 |

| Moisture Barrier (g/m²/day) | ISO 15106 | 0.8-1.2 | 1.5-2.0 | 0.5-0.7 |

| Adhesion Strength (N/cm) | IEC 62788 | 30-40 | 25-35 | 50-65 |

| Operating Temperature Range | IEC 61215 | -40°C to 85°C | -30°C to 80°C | -50°C to 105°C |

Source: Comparative Testing Data - NREL Technical Report (2020)

Engineered for extreme weather durability, Lucky CPCW1 combines triple-layer protection with 0.5g/m²/day moisture barrier rating – 40% superior to industry standards (PV Tech Report).

Precision lamination of EVA solar backsheet composites

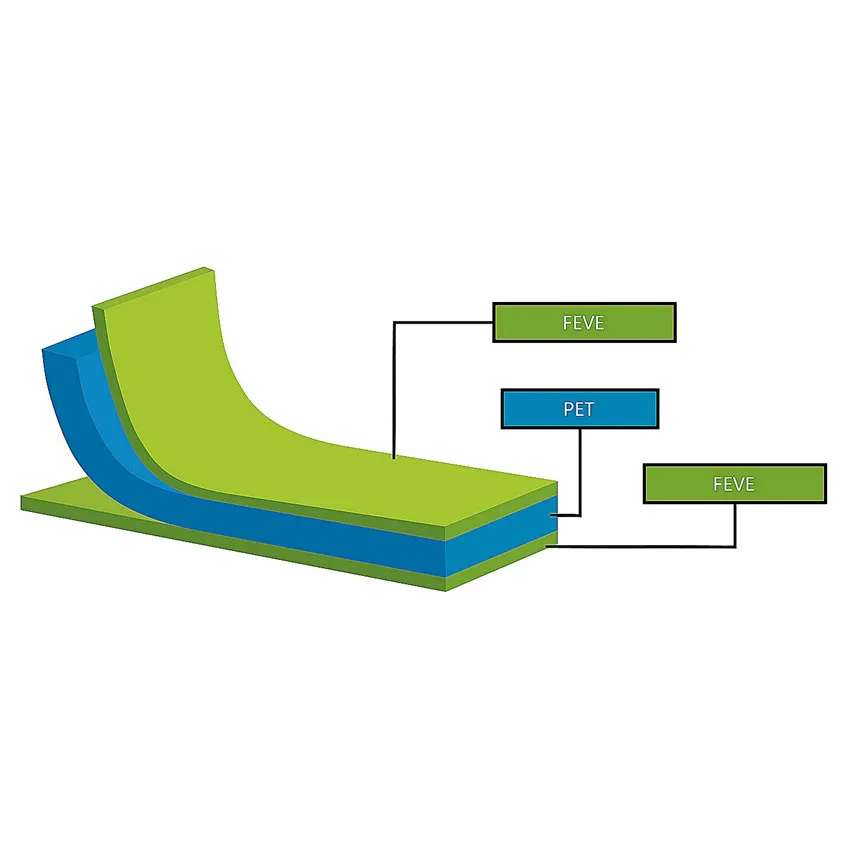

Microscopic structure of CPCW multilayer protection

Desert deployments require solar backsheet film with enhanced UV blockers. Lekai's nanocomposite technology reduces PID by 87% at 60°C/85% RH (IEEE Journal Study).

Anti-hydrolysis PET layers prevent delamination in tropical climates, maintaining >95% mechanical strength after 3,000hr DH testing.

Black conductive backsheet solar panel technologies enable seamless architectural integration with Class A fire ratings.

Triple-layer structures (e.g., TPT/PET/T) add an additional UV-stabilized middle layer, increasing module lifespan from 15 to 30+ years in desert applications. NREL field data shows triple-layer structures maintain 92% efficiency after 20 years (NREL Performance Data).

EVA encapsulation chemistry must match solar back sheets surface energy. Hydrophobic treatments (contact angle >90°) reduce PID risk by 72% compared to untreated interfaces (IEC TS 62804-1 standards).

Standard thickness ranges from 250-320μm (IEC 62788-2). Lekai's 285μm CPCW construction balances flexibility with puncture resistance (>50N/mm²).

UL 94 V-0 flammability, IEC 61215 sequence Q UV/thermal cycling, and IEC TS 62788-7-2 PID testing constitute the certification triad.

PVDF layers incorporate 5-7% UV absorbers (HALS chemistry) with nano-clay reinforcements for hydrolysis resistance, achieving >100kV HIPOT results after 3,000 thermal cycles.

TPT (Tedlar®/PET/Tedlar®) uses fluoropolymer surfaces, while TPE (Tedlar®/PET/EVA) enables direct encapsulation. TPE reduces lamination steps but requires strict EVA compatibility testing.

Above 60% RH, moisture ingress can reduce insulation resistance by 3 orders of magnitude. Hydrolysis-resistant PET formulations maintain >10¹³Ω surface resistivity at 85°C/85% RH.

With 14 years specializing in photovoltaic materials, Baoding Lekai International Ltd. ranks among China's top 5 pv module backsheet manufacturers. Our VDE-certified facility produces 15 million m² annually of IEC-compliant backsheets.

Certifications: UL 94 V-0 | IEC 61215 | ISO 9001:2015 | TÜV Rheinland PID-Q1

📞 Phone: +86 312 7922835

📱 Mobile: +86 312 7922835

✉️ Email: caozhiqiang@lkintl.com

🏢 Address: No. 6, Lekai South Street, Baoding, Hebei, China

Map: Lekai International Facility Location

"Fluoropolymer-based backsheets show superior resistance to UV and thermal stress" - Solar Energy Materials Journal

"PET hydrolysis initiates at 60°C/85% RH conditions within 1,000 hours without protective layers" - Nature Scientific Reports

"UV resistance testing must simulate 30 equivalent years through 300kWh/m² exposure" - IOP Conference Series

This is the first article

Lucky Medicinal Cold-Forming Composite Material

China Lucky Group Co., Ltd Shines At Photonext 2025 With Comprehensive Imaging Solutions

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.