X ray film remains an essential consumable in medical diagnostics, industrial NDT (Non-destructive Testing), and security applications. In a rapidly evolving industry rooted in innovation and strict regulatory standards, choosing the right film in x ray systems is critical for image quality, reliability, and patient or asset safety.

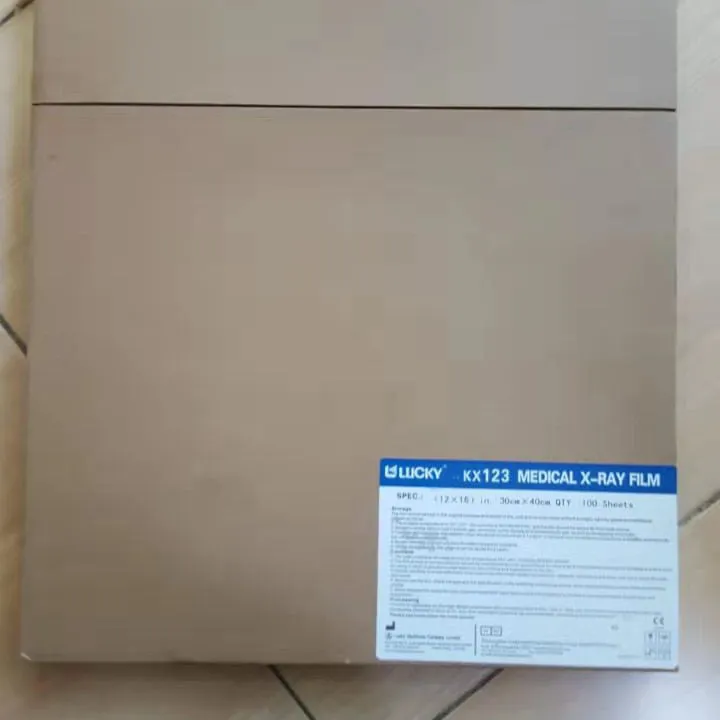

This report dissects the industry trends, critical technical parameters, state-of-the-art manufacturing processes, and leading products—including an in-depth review of Lucky Medical X Ray Film Kx123 &Kx171—for buyers, engineers, and procurement professionals needing superior x ray film for sale.

| Film Type | Base Material | Coating Type | Sensitivity (ISO) | Resolution (lines/mm) | Thickness (mm) | Typical Lifespan | Application |

|---|---|---|---|---|---|---|---|

| Blue-Sensitive X Ray Film | Polyester | Single/ Double Emulsion | ISO Class 400/800 | ≥16 | 0.175 | 10 years | Medical radiology, NDT |

| Green-Sensitive X Ray Film | Polyester | Double Emulsion | ISO Class 100/200 | ≥18 | 0.18 | 8–10 years | General radiography |

| Industrial X Ray Film | Polyester | Double Emulsion | ANSI/AAMI | ≥13 | 0.19 | 8 years | NDT, pipeline, petrochemical |

| Dental X Ray Film | Cellulose Triacetate | Single Emulsion | ISO Class 100 | ≥14 | 0.18 | 5 years | Dental radiology |

| Parameter | Kx123 (Blue-sensitive) | Kx171 (Green-sensitive) |

|---|---|---|

| Base Material | Polyester, 0.175 mm | |

| Spectral Sensitivity | Blue, ~450 nm | Green, ~540 nm |

| ISO Class | 400 | 200 |

| Resolution (lines/mm) | 17 | 18 |

| Density (Dmax) | 3.2 | 3.1 |

| Typical Sizes | 8x10”, 10x12”, 11x14”, 14x17” | |

| Certification/Standards | ISO 11699, FDA, CE | |

| Archival Life | 10 years (ISO 18901) | |

| Brand / Supplier | Country | Flagship Model | Certifications | Specialty |

|---|---|---|---|---|

| Lucky Medical | China | Kx123, Kx171 | ISO 11699, FDA, CE | Broad range, medical & industrial, strong price-performance |

| FujiFilm | Japan | HR-A, UM-MA | ISO, FDA, CE | Premium resolution, extra-fine grain |

| Agfa | Belgium | CP-GU, CP-BU | ISO, CE | Stability, European compliance |

| Kodak Carestream | USA | TXP, MXBE | FDA, ISO | Diversified imaging segments |

| Konica Minolta | Japan | SRX-S, Super RX | ISO, CE | Medical specialty, dental, vet |

This is the first article

Lucky Medicinal Cold-Forming Composite Material

China Lucky Group Co., Ltd Shines At Photonext 2025 With Comprehensive Imaging Solutions

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.