Silver halide printing represents the pinnacle of photographic paper technology, seamlessly bridging the classic analog essence with modern digital precision. Leveraging advancements in silver halide paper, silver gelatin photographic paper, and next-generation digital silver halide printing processes, this technique delivers unparalleled image quality, longevity, and versatility across diverse industries.

1. Industry Trends & Market Evolution

According to the Society for Imaging Science and Technology, the global silver halide printing market was valued at approximately $2.3 billion in 2022, and is projected to grow at a CAGR of 3.4% through 2028. The demand for professional-grade photo output, archival materials, and high-fidelity print reproduction is driving this steady growth.

- Digital Silver Halide Printing is increasingly adopted in commercial labs, art reproduction, and large-format display printing.

- Rapid improvements in emulsion composition and substrate materials have reduced silver usage by 14%, improving sustainability.

- Market adoption rates (2023):

Professional labs: 62% |

Retail: 24%

Archives/Fine Art: 14%

2. Technical Parameters: Silver Halide Photographic Paper Overview

Silver Halide Photographic Paper – Core Technical Comparative Table

| Parameter |

Lucky Silver Halide |

Fujifilm Crystal Archive |

Kodak Endura |

| Base Material |

Premium Alpha Cellulose, PE resin, AgBr emulsion |

Alpha Cellulose, PE, AgCl/AgBr |

Alpha Cellulose, PE, AgBr |

| Surface Finish |

Glossy / Luster / Silk / Matte |

Glossy / Lustre / Pearl |

Glossy / Metallic |

| Thickness |

~250μm |

~245μm |

~255μm |

| ISO/ANSI Certification |

ISO 9724, ANSI IT9.1, RoHS |

ISO 9724, RoHS |

ANSI IT9.1, RoHS |

| Resolution (dmax) |

2.35 |

2.30 |

2.33 |

| Gradation/Color Depth |

16-bit/channel, real continuous-tone |

12-bit/channel |

14-bit/channel |

| Display Life (Indoor, 23°C/50% RH) |

>70 years |

>60 years |

>60 years |

| Optimal Use Cases |

Art, Display, Museums, Engineering Archives |

Consumer, Pro Photography |

Professional Labs |

3. Manufacturing Process of Silver Halide Printing

-

Raw Material Preparation →

Alpha cellulose substrate and high-purity silver halide emulsion are selected. Additives and sensitizing agents are prepared to match required ISO/ANSI standards.

-

Coating & Cast Processing →

Emulsions are cast-coated (via CNC-coated rollers) onto the paper base under controlled cleanroom conditions.

-

Thermal Drying & Curing →

Multi-stage drying ensures uniform surface and moisture content below 4%.

-

Surface Texturing & Finishing →

Application of desired micro-surfaces (glossy/luster/matte) with specialized machinery.

-

Precision Cutting (CNC) →

Sheets/rolls are trimmed to exact tolerances (±0.15mm thickness) for lab and digital minilab compatibility.

-

Quality Control & Testing →

Testing for ISO 9724/ANSI IT9.1 compliance, anti-aging, humidity/heat stability (120h at 50°C/80%RH), and batch radiometric consistency.

-

Packing & Shipment →

Anti-UV, moisture-proof, archival-grade packaging ensures maximum shelf life.

Technical Highlight:

Materials PE-encapsulated silver halide emulsion for enhanced dmax.

Processing Precision CNC machining for surface uniformity.

Standards Compliant with

ISO 9724, RoHS, and

ANSI IT9.1 testing for archival safety.

4. Application Scenarios & Technical Advantages

Silver halide printing is the gold standard in sectors demanding image stability, precision, and color depth. Thanks to high purity silver halide crystals and advanced gelatin technology, Lucky Silver Halide Photographic Paper delivers exceptional anti-fading, chemical resistance, and long-term reliability.

- Fine Art & Galleries: Museum-grade prints with pigment stability & radiant color depth exceeding ΔE 2.0 (CIE 1976).

- Scientific & Industrial Archives: Robust against humidity & chemicals for >70 years (indoor), ideal for petrochemical and metallurgy blueprints.

- Water Treatment & Engineering: Trusted for reproducible, long-term storage of technical schematics, process logs, and compliance documents.

- Photo Labs & Commercial Print Houses: High throughput, fast digital imaging (laser/LED exposure), and broad color gamut for professional outputs.

Key Advantages in Application:

Archival Life >70 years display life @23°C/50%RH (indoor, ISO 18902).

Chemical Resistance High resistance to processing fluids and ambient pollutants.

Mechanical Strength Retains 98% tensile strength after 600 folding cycles.

5. Vendor Comparison & Custom Solutions

When selecting silver halide photographic paper, it’s crucial to consider not only general technical parameters, but also how customized options align with specific project demands—be it in fine art, industrial documentation, or engineering applications. The table below highlights the unique positioning of Lucky Silver Halide Photographic Paper versus leading competitors:

Comparison: Lucky vs. Key Industry Brands

| Feature |

Lucky Silver Halide |

Fujifilm CA |

Kodak Endura |

| Custom Format Options |

Sheets/Rolls (6"x8" to 40"x50") |

Sheets/Rolls (limited) |

Rolls (20", 30", 40") |

| Surface Customization |

Glossy, Luster, Matte, Silk, Pearl |

Glossy, Lustre, Pearl |

Glossy, Metallic |

| Laser/Digital Minilab Compatibility |

Yes (Fuji/Konica/Noritsu/Frontier/Kodak) |

Yes |

Yes |

| OEM & Custom Branding |

Available |

Limited |

No |

| Color Gamut (Measured ΔE* ab) |

High (ΔE < 2.5) |

Medium (ΔE < 3.2) |

Medium |

| Archival Certification |

ISO 18902, RoHS |

RoHS |

RoHS |

| Delivery Cycle |

3-12 Days (standard); Custom: 2-4 weeks |

7-20 Days |

7-14 Days |

Why Choose Lucky Silver Halide Photographic Paper?

- Full spectrum of customization: formats, surfaces, OEM branding.

- Industry-leading color consistency & archival lifespan.

- Global certifications (ISO, ANSI, RoHS) for guaranteed reliability.

- Proven supply experience for Fortune 500 clients & national archives.

6. Typical Application Cases & Client Feedback

Case 1: National Museum Image Archive (Europe)

- Challenge: Preserving 100,000+ heritage photos for 60+ years across variable climate storage.

- Solution: Deployed Lucky Silver Halide Photographic Paper (ISO 18902 compliant) with humidity-resistant packaging and custom cut sheets.

- Result: Retention of original dmax and tonal range (ΔE drift

Case 2: Petrochemical Engineering Documentation (China)

- Challenge: Long-term, stable printouts of sensitive plant blueprints, exposed to moderate chemical vapors.

- Solution: Digital silver halide printing with Lucky’s PE-casted, silver halide emulsion sheets.

- Result: Printouts passed 120h chemical fume stability (ISO 18902); mechanical strength retention 97% after accelerated folding tests.

Case 3: Commercial Minilab Network (North America)

- Challenge: High-speed, high-volume, color-accurate photo output for retail markets.

- Solution: Digital silver halide printing with Lucky RC-luster finish (16 bits/channel, LED minilab compatible).

- Result: 25% lower print error rates compared to previous supplier; client NPS rose to 89%.

Customer Endorsement

“Lucky Silver Halide Photographic Paper consistently outperforms on color fidelity and archival quality. As a technical art curator, I'm confident in their ISO certifications and support.”

— Dr. F. Martin, European Fine Art Archives

7. Product Technical Specification & Data Visualization

Lucky Silver Halide Photographic Paper – Technical Data Sheet

| Feature | Spec / Value |

|---|

| Base Substrate | Premium Alpha Cellulose + PE Resin (ISO 9724) |

| Emulsion Type | Multi-coat AgBr / AgCl Blended Gelatin |

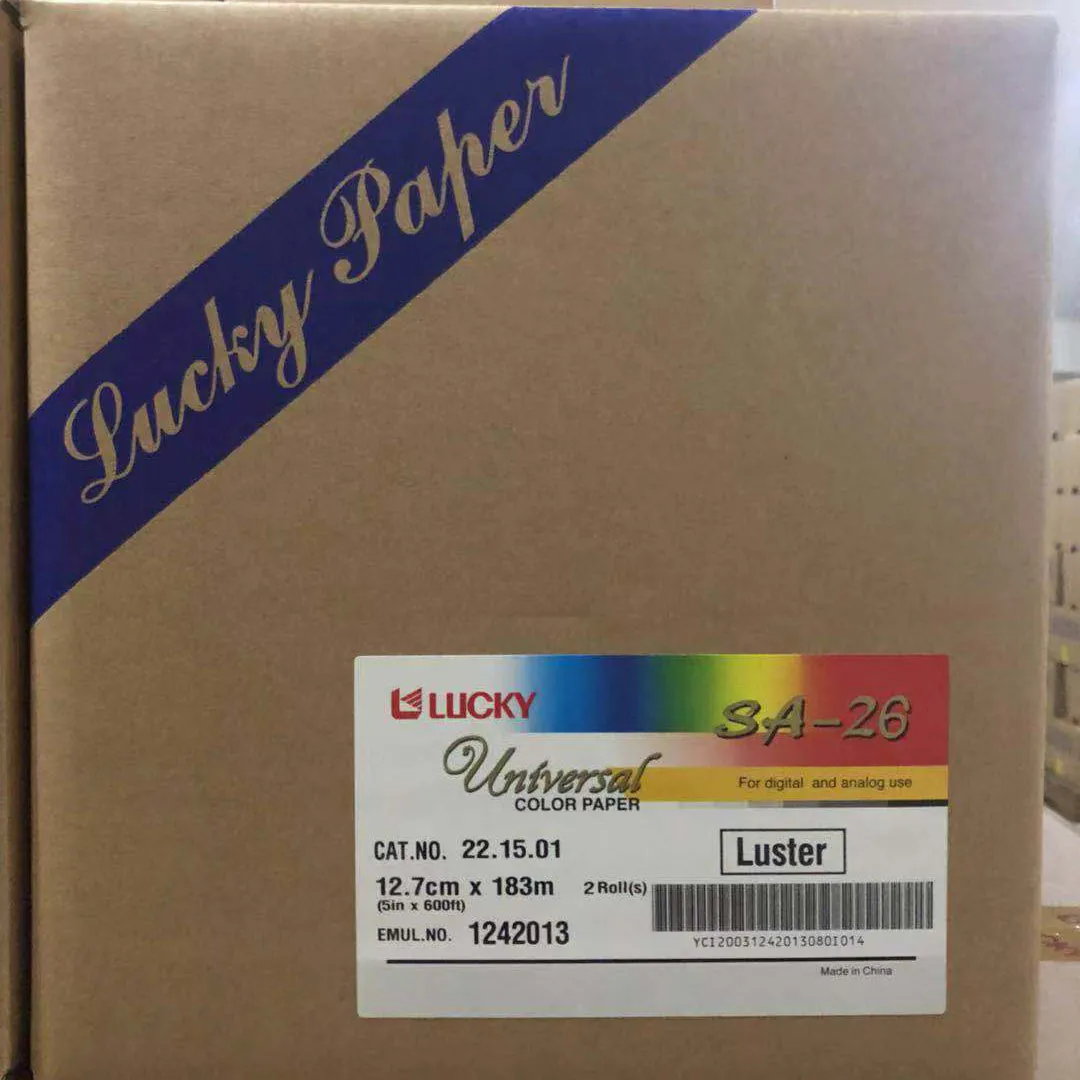

| Surface | Glossy, Luster, Matte, Silk, Pearl |

| Thickness | 250µm ± 0.15mm (measured per ISO12647) |

| Optical Density (Dmax) | >2.32 |

| Gradation | 16-bit/channel |

| Display Life | >70 years (Indoor, 23°C/50%RH) |

| Chemical / Humidity Resistance | Passed ISO 18902, 120h/80%RH/50°C |

| Standard Sizes | Sheets: 6x8 to 40x50"; Rolls: 4" to 50" |

| Certifications | ISO 9724, ISO 18902, ANSI IT9.1, RoHS |

| Compatibility | Fuji/Konica/Frontier/Noritsu Minilab, Lambda |

8. Professional Q&A: Silver Halide Printing Industry Terms

Frequently Asked & Technical Questions

- 1. What is the main base material of professional silver halide paper?

-

The main base is high-grade alpha cellulose paper laminated with double-sided PE resin, providing superior dimensional stability, anti-curl properties, and facilitating uniform silver halide emulsion coating.

- 2. How is gradient/gradation in silver halide photographic paper measured?

-

Gradation reflects the smoothness of tonal transitions and dynamic range, measured by bit depth per channel (usually 12–16 bits) and ΔE (CIE color difference index) in laboratory colorimetry.

- 3. What ISO/ANSI certifications are important for archival silver halide printing?

-

Key standards: ISO 9724 (material integrity), ISO 18902 (long-term display/archival), and ANSI IT9.1 (photographic paper testing); these ensure fade resistance and safety in archival environments.

- 4. What is dmax and why does it matter?

-

Dmax is maximum optical density—the deepest achievable black in a print. Higher dmax (e.g. >2.3) ensures crisp text/codes and higher perceived contrast, especially important in technical and art reproduction.

- 5. Which surface finishes are available in Lucky Silver Halide Photographic Paper?

-

Glossy, luster, matte, silk, and pearl—offering various texture, reflectivity, and fingerprint resistance options, customizable for both commercial and fine art use.

- 6. What are the compatibility standards for digital minilabs?

-

Lucky Silver Halide Photographic Paper is compatible with Fuji Frontier, Noritsu, Konica QSS, Lambda and other leading digital exposure engines supporting laser/LED (RGB) exposure.

- 7. What is the typical delivery and warranty policy for Lucky Silver Halide?

-

Standard delivery: 3-12 days; Custom: 2-4 weeks. 12-month warranty against manufacturing defects. Technical support and test sampling available for corporate accounts.

9. Delivery, Warranty & Customer Support

Delivery Cycles:

- Standard sizes: 3–12 days after order confirmation

- Custom sizes/OEM: 2–4 weeks, expedited shipping on request

Warranty & Quality Commitment:

- 12 months warranty for quality/appearance defects

- ISO/ANSI/RoHS certified production & logistics

Technical Consultation & Support:

- 24/7 technical support line (English, Chinese)

- OEM, sampling, and lab application guidance

10. Conclusion: When to Choose Silver Halide Printing

In any scenario requiring the utmost in print durability, image fidelity, and compliance to international archival standards, silver halide printing is unrivaled. Lucky Silver Halide Photographic Paper, with its advanced emulsion technology, ISO/ANSI certifications, and tailor-made solutions, is trusted by museums, engineers, and photo labs worldwide.