In the rapidly expanding solar energy sector, the reliability and longevity of photovoltaic (PV) modules are paramount. A critical, yet often overlooked, component contributing to this durability is the solar backsheet. Serving as the outermost layer of a PV module, the backsheet provides essential electrical insulation, mechanical protection, and environmental barrier functions. Selecting the right materials and partnering with competent solar backsheet suppliers is crucial for ensuring the long-term performance and safety of solar installations. This article delves into the technical aspects, manufacturing processes, and key considerations for choosing advanced backsheet solutions, highlighting the capabilities of products like Lucky Cpcw1 Solar Backsheet. We aim to provide B2B decision-makers and technical personnel with comprehensive insights to make informed procurement decisions.

The demand for high-performance solar backsheets is driven by an industry-wide push for higher efficiency, extended product warranties, and resilience against increasingly harsh environmental conditions. As solar technology evolves, so too must the materials that encapsulate and protect PV cells. Understanding the intricate balance of material science, manufacturing precision, and rigorous testing is key to unlocking the full potential of solar module longevity.

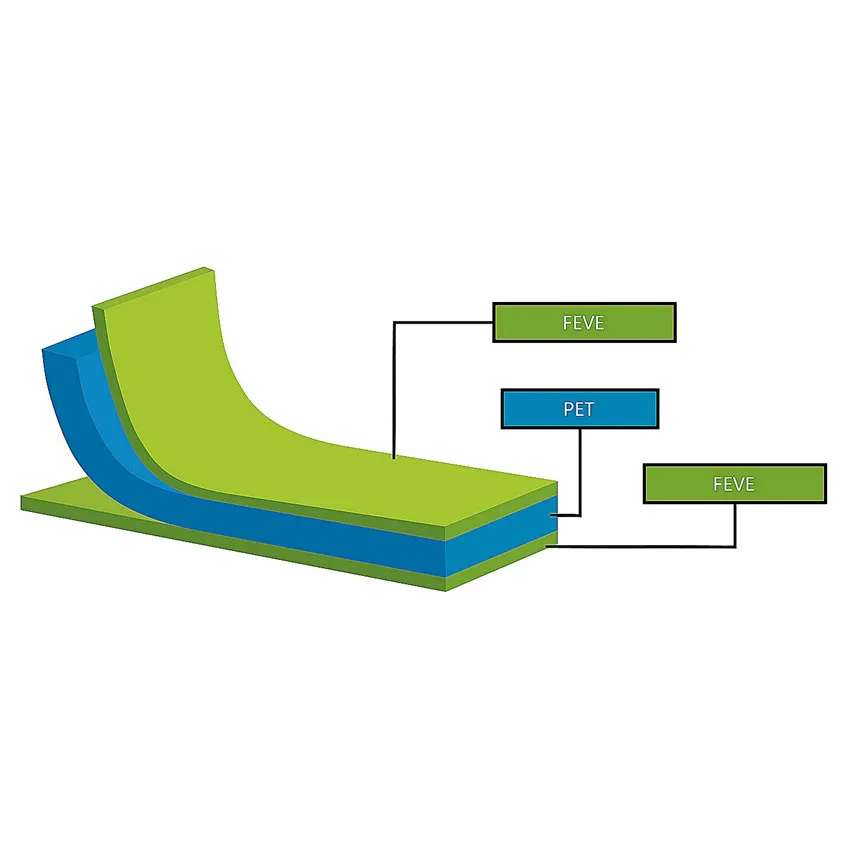

A solar backsheet material is primarily designed to protect the sensitive internal components of a PV module from environmental degradation while providing electrical insulation. The most common types include multi-layer laminates incorporating fluoropolymers like PVDF (polyvinylidene fluoride) and PVF (polyvinyl fluoride, e.g., Tedlar®), and polyester (PET) films. A typical structure might be TPT (Tedlar®-PET-Tedlar®) or KPC (Kynar®-PET-Coating), where the outer fluoropolymer layers offer superior UV resistance, weatherability, and chemical stability, while the inner PET layer provides mechanical strength and adhesion.

The core functions of a solar backsheet film include:

The evolution of solar backsheets has seen a shift towards more cost-effective and environmentally friendly solutions, including various non-fluorine options that still meet stringent performance requirements through advanced coating technologies. For instance, EVA solar backsheet is a common term referring to backsheets designed to optimally bond with EVA encapsulant, ensuring long-term adhesion and preventing delamination. Suppliers continuously innovate to enhance features like PID (Potential Induced Degradation) resistance, high reflectivity for increased efficiency, and compatibility with bifacial modules.

The production of high-quality solar back sheets involves several sophisticated steps, ensuring each layer contributes optimally to the final product's performance. The process typically begins with the preparation of base films, such as PET, which provide the structural backbone. Subsequent stages involve precise coating and lamination techniques to apply functional layers.

Throughout this process, stringent quality control measures are implemented. This includes in-line monitoring of film thickness, coating uniformity, and adhesion strength. Post-production, extensive testing is conducted to ensure compliance with international standards such as IEC 61215 (design qualification and type approval) and IEC 61730 (safety qualification). These standards mandate tests for UV aging, damp heat, thermal cycling, partial discharge, and dielectric breakdown voltage. The longevity of a backsheet can significantly influence the overall service life of a PV module, often targeted at 25-30 years or more.

The primary applicable industry for solar backsheet suppliers is, unequivocally, the solar energy sector. This includes manufacturers of residential, commercial, and utility-scale PV modules. The critical advantage of high-performance backsheets in these applications lies in their ability to provide long-term protection, preventing issues like delamination, cracking, and yellowing, thereby maintaining module efficiency and ensuring a stable return on investment over decades.

The performance of a pv module backsheet is quantifiable through various technical parameters, which are critical for engineers and procurement specialists. These parameters define the backsheet's ability to withstand environmental stresses and provide robust protection over its operational lifetime. Understanding these benchmarks helps in evaluating and comparing offerings from different solar backsheet suppliers.

| Parameter | Description | Typical Range (IEC Standard) | Lucky Cpcw1 Advantage |

|---|---|---|---|

| Dielectric Breakdown Voltage (DBV) | Maximum voltage a backsheet can withstand before electrical breakdown. Essential for safety and insulation. | >1000V (min.), >1500V (enhanced) | >2000V, ensuring superior electrical safety margin. |

| Partial Discharge (PD) Inception Voltage | Voltage at which partial discharges begin, indicating potential long-term insulation degradation. | >1000V | >1500V, mitigating insulation aging risks effectively. |

| Water Vapor Transmission Rate (WVTR) | Rate at which water vapor passes through the material. Lower values indicate better moisture barrier. | <5 g/m²·day (standard) | <2 g/m²·day, significantly reducing moisture ingress. |

| UV Aging Resistance | Ability to withstand prolonged UV exposure without yellowing, cracking, or delamination. (Measured in kWh/m²). | >60 kWh/m² | >120 kWh/m², doubling standard endurance for harsh climates. |

| Tensile Strength (MD/TD) | Material's resistance to breaking under tension in machine direction (MD) and transverse direction (TD). | >80 MPa (MD), >60 MPa (TD) | >100 MPa (MD), >80 MPa (TD), ensuring robust mechanical durability. |

| Adhesion Strength (to EVA) | Bonding strength between the backsheet and the EVA encapsulant. Critical for preventing delamination. | >50 N/cm | >80 N/cm, promoting long-term module integrity. |

The Lucky Cpcw1 Solar Backsheet excels across these critical parameters, offering superior dielectric strength, exceptionally low WVTR, and outstanding UV resistance, making it an ideal choice for modules deployed in diverse and challenging environments. Its optimized multi-layer structure provides enhanced protection against potential induced degradation (PID) and maintains high reflectivity, subtly contributing to overall module efficiency by minimizing light absorption at the rear.

Investing in advanced solar backsheets from reputable solar backsheet suppliers provides a cascade of benefits that directly impact the return on investment for solar projects. These advantages extend beyond mere protection, influencing overall system reliability, longevity, and even efficiency.

For manufacturers, integrating a high-quality pv module backsheet simplifies compliance with international standards and reduces warranty claims, strengthening their brand reputation. For developers and asset owners, it means more reliable power generation and a more secure investment.

Choosing the right solar backsheet suppliers involves more than just product specifications; it encompasses a partnership that provides expertise, reliability, and tailored solutions. Leading suppliers offer not only high-performance materials but also comprehensive technical support, flexible delivery options, and robust after-sales service.

Our experience working with global PV manufacturers highlights the importance of customized solutions. For example, in a large-scale desert utility project requiring extreme sand abrasion resistance, we provided a bespoke Lucky Cpcw1 Solar Backsheet with an enhanced outer layer, exceeding standard durability tests. Similarly, for a rooftop project in a highly humid coastal region, our backsheet's ultra-low WVTR was critical in preventing premature degradation and ensuring long-term performance under severe damp heat conditions.

"Our collaboration with Lucky International on the 'Desert Bloom' project showcased their unparalleled ability to adapt. Their customized backsheet solution provided the robust protection our modules needed against extreme environmental stressors, contributing significantly to the project's success and our confidence in module longevity." - A leading global PV module manufacturer.

Beyond standard offerings, the ability to provide materials tailored to specific module designs (e.g., thinner films for flexible modules, specific colors for aesthetic integration, enhanced adhesion for specific encapsulants) sets apart truly valuable solar backsheet suppliers. This level of partnership ensures that the backsheet is not just a component, but an optimized part of the entire module system, contributing to maximum efficiency and resilience.

Trustworthiness in the B2B sector for solar backsheet suppliers is built upon demonstrable quality, adherence to international standards, and clear commitments. Reputable manufacturers provide comprehensive documentation and support.

A key aspect of supplier reliability is the ability to maintain consistent delivery schedules and offer robust warranties. For Lucky Cpcw1 Solar Backsheet, standard delivery cycles are typically 3-4 weeks for general orders, with expedited options available for urgent requirements. Our products come with a minimum 10-year material warranty, guaranteeing performance against defects and premature degradation, reinforcing the long-term investment in our solutions.

Beyond products, strong customer support is vital. This includes technical assistance for integration, troubleshooting, and post-sales inquiries. Our dedicated team provides expert guidance on material selection, application best practices, and performance optimization, ensuring clients derive maximum value from Lucky Cpcw1 solar backsheet. This holistic approach builds confidence and fosters long-term partnerships.

The solar backsheet is far more than a simple protective layer; it is a critical engineering component vital to the long-term reliability and performance of PV modules. As the solar industry continues its rapid expansion, the role of expert solar backsheet suppliers in providing advanced, durable, and cost-effective solutions becomes increasingly significant. Companies like Lucky International, with their Lucky Cpcw1 Solar Backsheet, are at the forefront, offering materials that meet the stringent demands of modern PV applications and contribute to sustainable energy generation worldwide. By prioritizing rigorous testing, innovative material science, and comprehensive customer support, leading suppliers empower module manufacturers to deliver products with extended lifespans and reliable power output, ensuring a robust future for solar energy.

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Environmental Impact of DICOM Printer Usage

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.