In the rapidly expanding global solar energy sector, the longevity and efficiency of photovoltaic (PV) modules hinge significantly on the quality of their constituent materials. Among these, the solar backsheet stands as a paramount component, offering electrical insulation, environmental protection, and mechanical support to the delicate solar cells. As the industry advances, the demands on solar backsheet suppliers have intensified, pushing innovations in material science and manufacturing processes. These innovations are crucial for extending module lifespan, especially given the harsh environmental conditions PV installations face, from extreme UV radiation and high temperatures to humidity and mechanical stress. The selection of the right solar backsheet material is not merely a matter of cost but a critical investment in the long-term reliability and performance of solar power systems, directly impacting return on investment for large-scale solar farms and distributed generation alike. Understanding the intricate balance between material properties, manufacturing precision, and real-world application is essential for developers, EPCs, and investors seeking to optimize their solar assets. The evolution of `solar backsheet film` technology, moving towards more durable, efficient, and cost-effective solutions, underscores its importance in the global energy transition, ensuring that solar remains a competitive and sustainable energy source for decades to come.

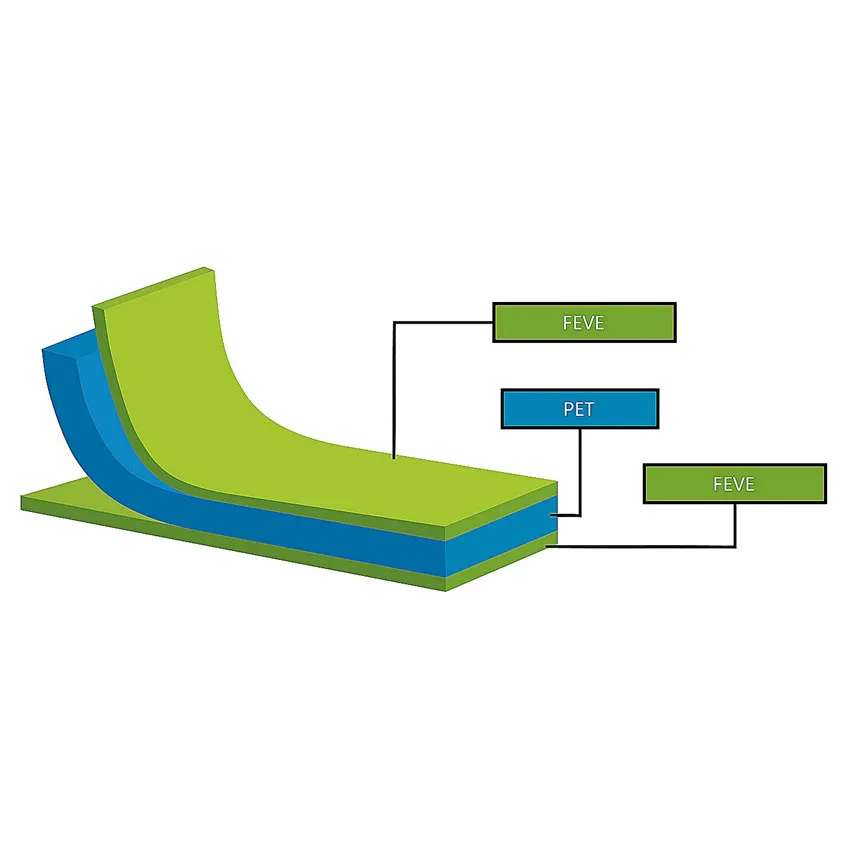

The manufacturing of high-quality `pv module backsheet` products involves sophisticated processes designed to impart superior protective qualities and durability. Unlike heavy industrial components requiring casting or forging, `solar backsheets` are meticulously produced through advanced lamination and extrusion techniques. These processes transform high-performance polymers into multi-layered structures, each layer serving a specific function. For instance, the outer layer, often made of fluoropolymer (e.g., PVDF or PVF), provides exceptional UV resistance and self-cleaning properties, shielding the module from degradation due caused by solar radiation. The core layer, typically polyethylene terephthalate (PET), offers excellent mechanical strength and electrical insulation, preventing potential induced degradation (PID) and ensuring module integrity. The inner layer, frequently an `eva solar backsheet` variant or similar adhesive, facilitates strong bonding with the EVA encapsulant, preventing delamination over time.

Rigorous inspection standards, including ISO 9001 for quality management and IEC 61215/61730 for module qualification, govern the production, ensuring every batch meets stringent performance criteria. Key tests include damp-heat (e.g., 85°C and 85% relative humidity for 1000 hours), UV exposure, thermal cycling, and partial discharge tests. These tests are critical for validating the `solar back sheet`'s projected lifespan, which typically exceeds 25 years in the field. Our Lucky Cpcw1 Solar Backsheet, for example, undergoes such rigorous testing, validating its superior performance in diverse environments. Its multi-layer structure is optimized through co-extrusion and adhesive lamination processes, ensuring uniform thickness, consistent dielectric strength, and high adhesion to the EVA encapsulant. The integration of advanced polymer compounding, precision coating, and automated lamination lines guarantees minimal defects and maximum reliability, providing a robust defense against environmental stressors for the entire lifespan of the solar panel.

The Lucky Cpcw1 Solar Backsheet represents the pinnacle of modern `solar backsheet material` technology, engineered to deliver exceptional long-term performance and reliability under challenging conditions. This product is specifically designed to meet the rigorous demands of global solar projects, from utility-scale solar farms in arid deserts to rooftop installations in humid coastal regions. Its unique formulation provides superior resistance to UV radiation, moisture ingress, and thermal stress, critical factors that can lead to premature module degradation. The Lucky Cpcw1 offers excellent dielectric insulation, ensuring electrical safety and preventing leakage currents, which are vital for system efficiency and operator safety. Furthermore, its mechanical properties, including high tear strength and puncture resistance, protect the solar cells from physical damage during installation and throughout the module's operational life. These attributes contribute significantly to the overall stability and longevity of solar panels, making it a preferred choice among leading `solar backsheet suppliers`.

The advanced composite structure of Lucky Cpcw1 utilizes a combination of optimized fluoropolymer outer layers and high-strength PET core, ensuring robust protection. This design not only enhances the module's resistance to environmental factors but also contributes to its energy efficiency by maintaining optimal internal temperatures and preventing hot spots. Its compatibility with various encapsulants and cell technologies makes it a versatile solution for different module designs. For example, its application in regions prone to heavy snowfall demonstrates its robust mechanical properties, preventing cracks or damage to the underlying cells. Similarly, in high-humidity coastal areas, its superior moisture barrier prevents corrosion of internal components, ensuring sustained power output. The integration of cutting-edge materials and a precise manufacturing process provides a `backsheet solar panel` solution that exceeds industry expectations, translating into consistent energy yields and reduced maintenance costs for end-users.

| Parameter | Typical Value (Lucky Cpcw1) | Industry Standard (IEC 61730) | Benefit to Module |

|---|---|---|---|

| Dielectric Breakdown Strength | ≥ 25 kV/mm | ≥ 15 kV/mm | Exceptional electrical insulation, preventing short circuits and ensuring safety. |

| UV Resistance (Damp-Heat 85/85) | No yellowing after 3000 hrs | Minimal yellowing after 1000 hrs | Maintains aesthetic and protective properties under prolonged sun exposure. |

| Partial Discharge (PD) | ≤ 5 pC (at 1000V) | ≤ 10 pC | Prevents long-term insulation degradation, enhances module lifespan. |

| Adhesion Strength (after aging) | ≥ 50 N/cm | ≥ 30 N/cm | Ensures layers remain bonded, preventing delamination and moisture ingress. |

| Tensile Strength (MD/TD) | ≥ 80 MPa / ≥ 70 MPa | ≥ 50 MPa / ≥ 40 MPa | High mechanical durability against external forces (wind, snow). |

| Water Vapor Transmission Rate (WVTR) | ≤ 1.0 g/m²/day | ≤ 2.0 g/m²/day | Minimizes moisture penetration, critical for preventing cell corrosion. |

The strategic deployment of high-performance `solar backsheet film` is crucial across various application scenarios within the photovoltaic industry. From vast utility-scale solar farms stretching across deserts to distributed rooftop installations in bustling urban environments and even specialized off-grid solutions, the backsheet’s integrity directly influences system reliability and energy output. For utility-scale projects, where thousands of modules are exposed to consistent, harsh weather, the durability of the `solar backsheet` ensures long-term power generation and minimizes maintenance costs. In residential and commercial rooftop applications, the aesthetics and fire resistance of the `pv module backsheet` are equally important, alongside its protective qualities, ensuring safety and architectural integration. The demand for `solar backsheets` that can withstand extreme temperature fluctuations, high humidity, and continuous UV exposure is paramount, especially as solar energy penetration increases globally.

Our Lucky Cpcw1 Solar Backsheet has demonstrated exceptional performance in diverse global projects. For instance, in a large-scale project located in the Middle Eastern desert, the Cpcw1's advanced UV and sand abrasion resistance ensured minimal degradation, maintaining module efficiency and extending the project's operational lifespan beyond initial projections. Another successful application involved a floating solar farm in Southeast Asia, where the backsheet's superior moisture barrier properties were crucial in preventing water ingress and potential-induced degradation (PID) in a highly humid environment. These real-world applications underscore the critical role of choosing robust `solar backsheet suppliers` who provide materials engineered for specific environmental challenges. By providing enhanced protection against environmental stressors, these advanced `solar backsheets` significantly reduce the risk of premature module failure, thereby safeguarding energy yield and ensuring a robust return on investment for long-term solar assets. The proven track record of Lucky Cpcw1 across these varied and demanding scenarios highlights its capability to enhance the overall resilience and efficiency of solar photovoltaic systems, cementing its position as a leading choice for module manufacturers worldwide.

Selecting the appropriate `solar backsheet suppliers` is a strategic decision that directly impacts the long-term viability and profitability of solar energy projects. Beyond merely providing a product, a reputable supplier offers deep technical expertise, customization capabilities, and unwavering commitment to quality and support. When evaluating `solar back sheet` providers, it's essential to consider their R&D capabilities, their adherence to international quality standards (such as ISO 9001, ISO 14001, and IEC certifications), and their track record in delivering consistent performance under diverse conditions. The ability to offer tailored `solar backsheet material` solutions, for instance, a specific thickness for flexible modules or enhanced fire resistance for building-integrated photovoltaics (BIPV), differentiates a leader from a commodity provider.

Our company prides itself on not only supplying the high-performance Lucky Cpcw1 Solar Backsheet but also on our comprehensive customer support and flexible customization options. We understand that each module manufacturer and project developer has unique requirements, influenced by geographical location, specific environmental stresses, and module design. Our engineering team collaborates closely with clients to fine-tune `solar backsheets` specifications, ensuring optimal compatibility and performance. This includes adjusting material compositions for enhanced `eva solar backsheet` compatibility, varying layer thicknesses to meet specific dielectric strength requirements, or incorporating specialized additives for increased chemical resistance. With decades of experience in the polymer and materials science sector, our expertise extends beyond manufacturing to providing insightful consultation on material selection, module integration, and long-term performance predictions. This dedication to partnership and innovation is what makes us a trusted choice for `solar backsheet suppliers` worldwide, ensuring that every solution provided is perfectly aligned with the client's operational goals and long-term success.

Trust is the bedrock of any successful B2B relationship, especially in critical component supply chains like that for `solar backsheets`. We believe in full transparency and robust support to build and maintain this trust. Below are answers to common questions, alongside our commitments regarding delivery and warranty, reinforcing our position as reliable `solar backsheet suppliers`.

We maintain robust supply chain logistics to ensure timely and efficient delivery of our `solar backsheet` products globally. Our standard lead times are competitive, and we offer flexible shipping options to meet urgent project timelines. Each batch undergoes stringent quality control inspections before dispatch, adhering to ISO and IEC standards, ensuring that every roll of Lucky Cpcw1 Solar Backsheet meets the specified technical parameters.

We stand behind the quality of our products with a comprehensive product warranty covering manufacturing defects and performance under normal operating conditions. Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-purchase support required, ensuring a seamless experience from inquiry to installation. This commitment reinforces our reputation as highly dependable `solar backsheet suppliers` who prioritize client success and long-term partnerships.

The continuous evolution of `solar backsheet material` and manufacturing techniques is fundamental to the advancement of photovoltaic technology. As `solar backsheet suppliers`, our commitment to innovation, quality, and customer-centric solutions ensures that Lucky Cpcw1 Solar Backsheet remains at the forefront of this critical component category. By providing superior protection against environmental degradation, ensuring electrical integrity, and offering long-term durability, our `solar backsheet` products contribute directly to the higher performance, longer lifespan, and greater economic viability of solar power systems worldwide. The selection of a high-quality `pv module backsheet` is not merely a technical specification but a strategic decision that underpins the success and sustainability of solar energy investments. As the global energy landscape increasingly shifts towards renewables, the reliability offered by advanced backsheet solutions like Lucky Cpcw1 will be indispensable in harnessing the full potential of solar energy, ensuring a stable and efficient power supply for future generations.

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Optimizing Dry Imaging Film Storage Conditions

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.