The Lucky KPCW1 Solar Backsheet represents a significant advancement in photovoltaic (PV) technology, offering exceptional environmental resistance, reliable bonding systems, and rigorous quality control. As the global demand for renewable energy grows, the need for durable and high-performance solar components becomes critical. This article delves into the core features, technical specifications, applications, and company background of the KPCW1 backsheet, supported by authoritative references and industry insights.

Environmental Resistance: A Shield Against Harsh Conditions

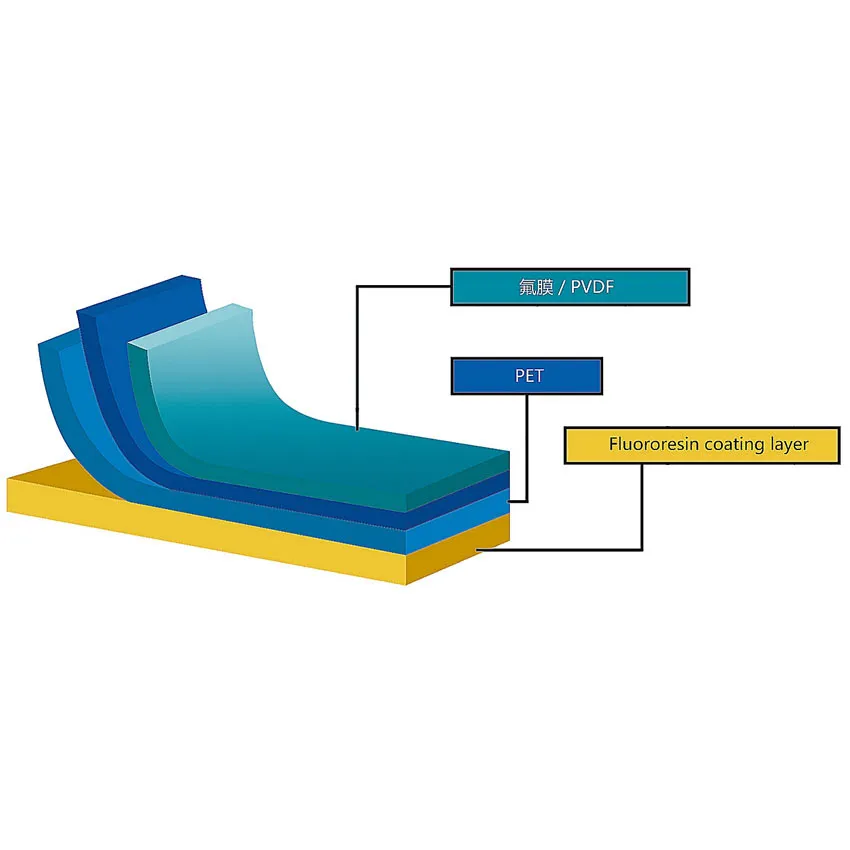

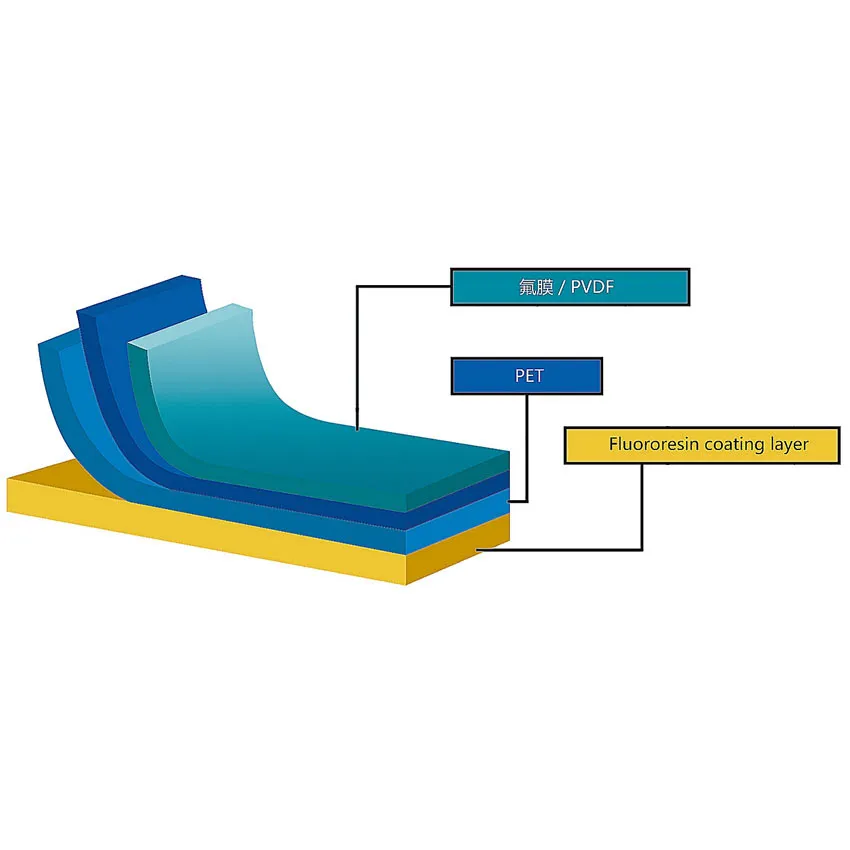

The KPCW1 solar backsheet is engineered with a PVDF fluoropolymer weather-resistant layer, which provides multiple protective characteristics to ensure long-term performance in challenging environments. According to the National Institute of Standards and Technology (NIST), standards for material durability are essential for renewable energy systems to withstand extreme conditions. The KPCW1 exemplifies these standards through its advanced design:

- UV Protection: The backsheet achieves an impressive over 95% UV blocking rate, safeguarding the PV module from degradation caused by ultraviolet radiation. NIST's research on photovoltaic materials emphasizes the importance of UV resistance in extending the lifespan of solar panels.

- Temperature Adaptability: It maintains stable performance across a wide temperature range, from -40°C to 85°C, making it suitable for both arid and cold climates. This adaptability aligns with NIST's guidelines for materials used in diverse environmental conditions.

- Weather Durability: The backsheet passes the 3000-hour dual 85 (85°C/85% RH) aging test, a stringent evaluation of long-term reliability. NIST's testing protocols for solar components highlight the necessity of such endurance tests to ensure safety and efficiency.

- Chemical Resistance: It effectively withstands exposure to acids, alkalis, solvents, and salt spray, which is crucial for coastal and industrial applications. NIST's studies on material corrosion resistance further validate the importance of this feature.

- Mechanical Properties: The backsheet retains over 90% tensile strength after damp heat aging, ensuring structural integrity under prolonged stress. This resilience is critical for meeting NIST's benchmarks for mechanical durability in renewable energy systems.

Reliable Bonding System: Ensuring Long-Term Performance

The KPCW1's fluorinated coating cured adhesive layer is designed to provide a robust bond between the backsheet and the PV module. Rigorous testing ensures its reliability:

- Peel Strength: With a peel strength of over 60 N/cm when bonded to EVA, the backsheet ensures long-term adhesion. NIST's research on adhesive materials underscores the importance of such metrics for structural integrity.

- Thermal Aging Stability: The bonding system demonstrates excellent interface stability after thermal aging tests, a critical factor for solar panels in fluctuating temperatures.

- Thermal Cycling Resistance: No delamination occurs after thermal cycling tests, ensuring the backsheet remains intact under repeated temperature changes.

- UV Resistance: It passes the 200kWh/m² UV accelerated aging test, a standard for evaluating long-term UV exposure resistance.

- Humid Environment Performance: The bond strength retention exceeds 85% in humid conditions, crucial for regions with high humidity or coastal areas.

Strict Quality Control: Ensuring Consistency and Reliability

Baoding Lekai International Ltd., the manufacturer of the KPCW1, employs a comprehensive quality control process to guarantee product consistency:

- Raw Material Inspection: Every batch of raw materials undergoes rigorous testing to ensure compliance with specifications.

- Real-Time Monitoring: Key production parameters are monitored in real time to maintain precision and uniformity.

- Appearance and Dimensional Inspection: 100% of finished products are inspected for appearance and dimensions to meet exacting standards.

- Accelerated Aging Tests: Regular sampling is conducted to simulate long-term performance under accelerated conditions.

- Traceability Records: Complete records are maintained for quality traceability, ensuring transparency and accountability.

Wide Range of Applications: Versatility for Diverse Environments

The KPCW1 is suitable for a variety of applications, including:

- Utility-Scale Solar Power Plants: Its durability makes it ideal for large-scale installations requiring long-term reliability.

- Commercial and Industrial Distributed Projects: The backsheet's performance ensures efficiency in diverse commercial settings.

- Coastal Areas with High Humidity: Its chemical and moisture resistance is critical for marine environments.

- High-Irradiation Desert Regions: The backsheet's UV protection and temperature adaptability are essential in arid climates.

- Regions with Large Temperature Variations: The material's thermal stability ensures consistent performance in extreme conditions.

Company Background: Baoding Lekai International Ltd.

Baoding Lekai International Ltd. (Chinese name: 保定乐凯进出口贸易有限公司) is a leading manufacturer and supplier of solar backsheet solutions. With a commitment to innovation and quality, the company has established itself as a trusted partner in the photovoltaic industry. Their R&D center and production facilities are designed to explore advancements in PV module technology, as highlighted in their company profile.

Product Specifications Table

| Parameter |

Specification |

| Material |

PVDF Fluoropolymer |

| UV Blocking Rate |

Over 95% |

| Temperature Range |

-40°C to 85°C |

| Weather Aging Test |

3000 hours at 85°C/85% RH |

| Chemical Resistance |

Acids, alkalis, solvents, salt spray |

| Tensile Strength Retention |

Over 90% after damp heat aging |

| Peel Strength (EVA) |

Over 60 N/cm |

| UV Accelerated Aging Test |

200kWh/m² |

| Bond Strength Retention (Humid) |

Over 85% |

Conclusion

The Lucky KPCW1 Solar Backsheet is a testament to the advancements in photovoltaic technology, combining cutting-edge materials, rigorous quality control, and versatile applications. Its ability to withstand extreme environmental conditions, coupled with a reliable bonding system, makes it an ideal choice for a wide range of solar projects. As NIST's research on material standards continues to evolve, the KPCW1 exemplifies the importance of innovation and durability in renewable energy solutions.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/