The Lucky KPCw1 Solar Backsheet represents a significant advancement in photovoltaic (PV) module technology, offering unparalleled environmental resistance, reliable bonding, and rigorous quality control. Developed by Baoding Lekai International Ltd., this product addresses the critical challenges faced by solar installations in diverse climatic conditions. This article delves into the technical specifications, applications, and industry relevance of the KPCw1 backsheet, supported by authoritative references and comprehensive data.

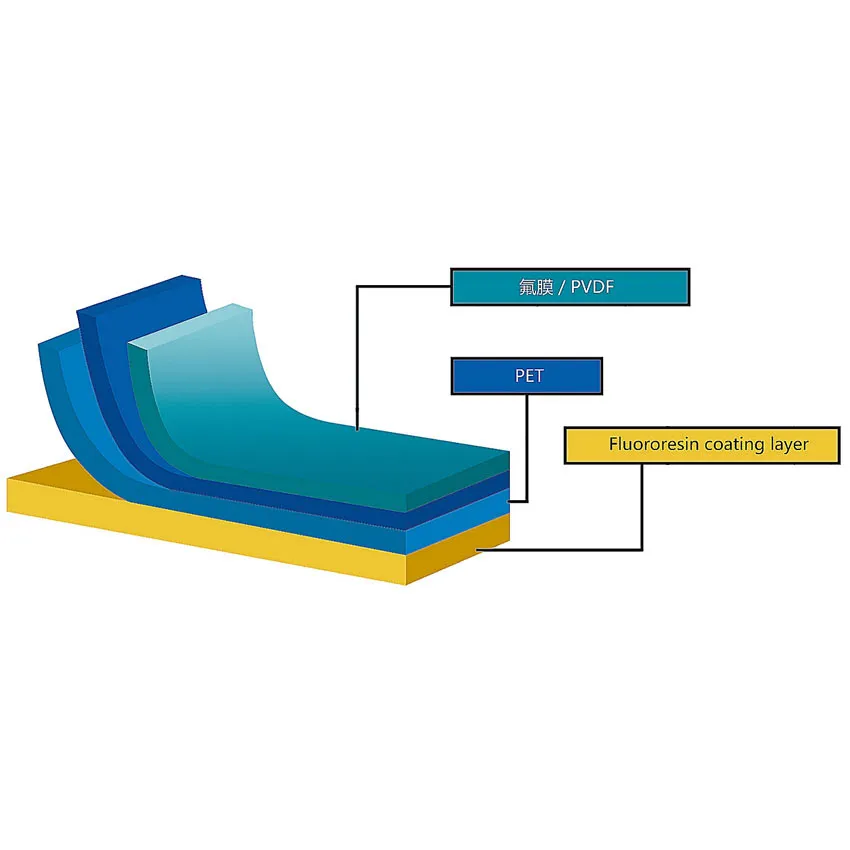

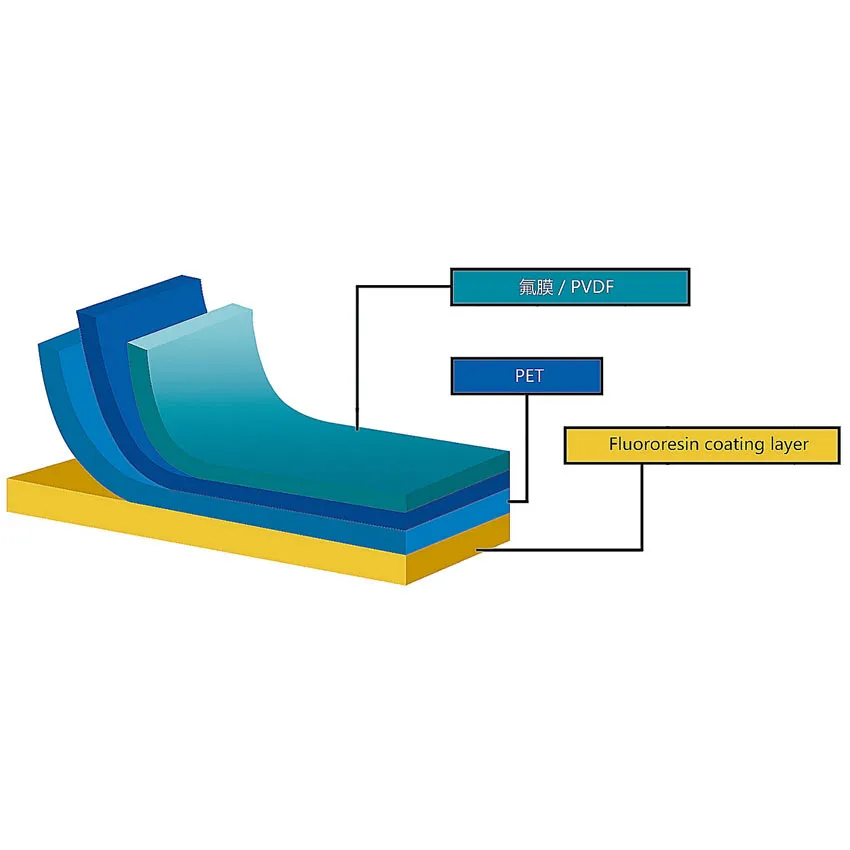

The KPCw1 Solar Backsheet is engineered with a PVDF fluoropolymer weather-resistant layer, which provides multifaceted protection for PV modules. This layer is designed to withstand the harshest environmental conditions, ensuring long-term performance and reliability. Key features include:

The KPCw1 backsheet features a fluorinated coating cured adhesive layer that ensures robust bonding with PV module components. This system has been rigorously tested to guarantee long-term performance:

Baoding Lekai International Ltd. employs a comprehensive quality control process to ensure the KPCw1 backsheet meets the highest standards:

The KPCw1 Solar Backsheet is designed for a variety of applications, including:

| Parameter | Specification |

|---|---|

| Material | PVDF Fluoropolymer |

| UV Blocking Rate | Over 95% |

| Temperature Range | -40°C to 85°C |

| Weather Aging Test | 3000-hour dual 85°C/85% RH |

| Chemical Resistance | Acids, Alkalis, Solvents, Salt Spray |

| Tensile Strength Retention | Over 90% after Damp Heat Aging |

| Peel Strength (EVA) | Over 60 N/cm |

| UV Accelerated Aging Test | 200 kWh/m² |

| Bond Strength in Humid Environments | Over 85% |

As a leading solar backsheet manufacturer, Baoding Lekai International Ltd. has dedicated itself to advancing photovoltaic technology through innovation and quality. The company's commitment to research and development is evident in the KPCw1 backsheet, which incorporates cutting-edge materials and testing protocols. With a focus on sustainability and performance, Baoding Lekai provides solutions for global solar energy projects, from utility-scale farms to distributed generation systems.

The company's R&D center and production facilities are equipped with state-of-the-art technology, ensuring that every product meets the stringent requirements of the renewable energy sector. By collaborating with industry partners and adhering to international standards, Baoding Lekai continues to set benchmarks for solar backsheet performance and reliability.

The Lucky KPCw1 Solar Backsheet exemplifies the synergy between advanced materials and rigorous engineering. Its environmental resistance, reliable bonding system, and strict quality control make it an ideal choice for solar installations in challenging conditions. As the demand for renewable energy grows, products like the KPCw1 play a crucial role in ensuring the longevity and efficiency of photovoltaic systems.

For further information on the KPCw1 backsheet, visit the product page or explore the company's website to learn more about Baoding Lekai International Ltd.'s contributions to the solar industry.

[1] National Institute of Standards and Technology (NIST). "Chemical Stability of Photovoltaic Materials." https://www.nist.gov/

[2] International Electrotechnical Commission (IEC). "IEC 61215: Crystalline Silicon Terrestrial Photovoltaic (PV) Modules - Design Qualification and Type Approval." https://www.iec.ch/

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Cost-Saving Strategies for High-Volume DICOM Printing

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.