The Lucky KPCW1 Solar Backsheet represents a significant advancement in photovoltaic (PV) module technology, offering unmatched environmental resistance and reliability. As the global demand for renewable energy grows, the need for durable, high-performance materials becomes critical. This article explores the Lucky KPCW1 Solar Backsheet's innovative features, technical specifications, and applications, while highlighting the company's commitment to quality and innovation. For more information on solar backsheet suppliers and manufacturers, visit Lucky's official website.

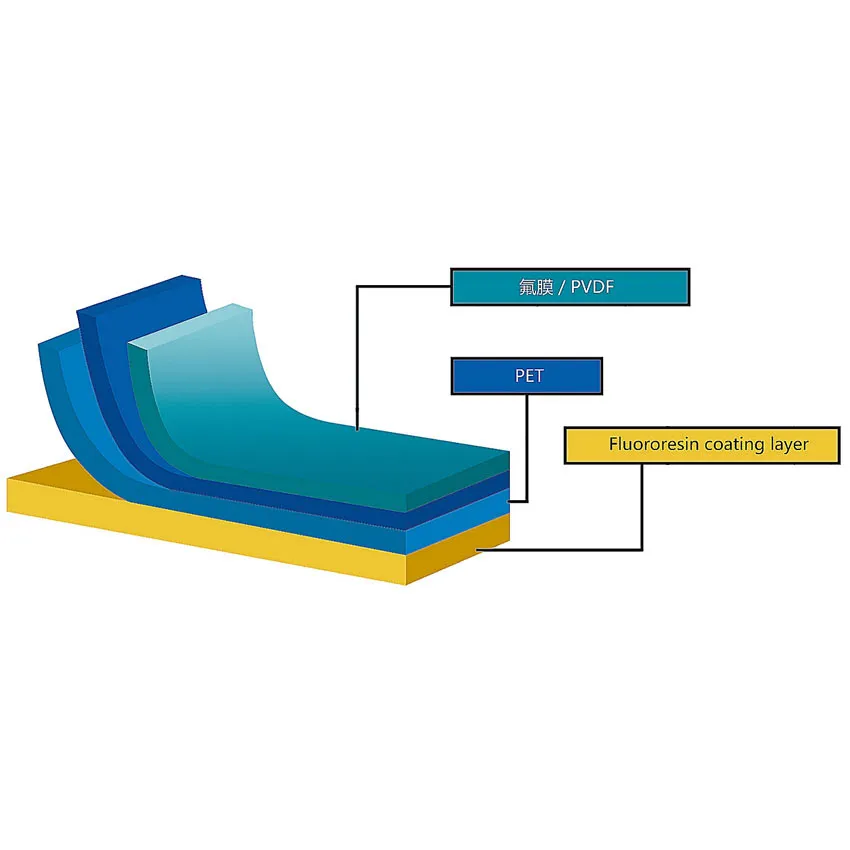

The Lucky KPCW1 Solar Backsheet is engineered with a PVDF fluoropolymer weather-resistant layer that provides exceptional protection against environmental stressors. This advanced material ensures long-term performance in even the most challenging conditions.

The backsheet's special formulation blocks over 95% of UV radiation, preventing degradation caused by prolonged sunlight exposure. This feature is crucial for maintaining the integrity of PV modules in high-irradiation regions, such as deserts. For insights into UV resistance standards, refer to the National Institute of Standards and Technology (NIST) guidelines on material durability.

Operating efficiently across a wide temperature range, the KPCW1 maintains stable performance from -40°C to 85°C. This makes it ideal for regions with extreme temperature fluctuations, such as coastal areas or high-altitude locations. The material's thermal stability is validated through rigorous testing, ensuring consistent energy output under varying conditions.

Passing the 3000-hour dual 85 (85°C/85% RH) aging test, the backsheet demonstrates exceptional resilience against humidity and heat. This certification underscores its suitability for utility-scale solar power plants and commercial distributed projects.

Engineered to withstand exposure to acids, alkalis, solvents, and salt spray, the KPCW1 resists corrosion and chemical degradation. This is particularly beneficial for installations in coastal areas or industrial zones where environmental contaminants are prevalent.

After damp heat aging, the backsheet retains >90% of its tensile strength, ensuring structural integrity over time. This durability is essential for maintaining the efficiency and safety of PV modules in harsh environments.

The KPCW1 features a fluorinated coating cured adhesive layer that guarantees robust adhesion to PV modules. This system has been rigorously tested to ensure long-term reliability.

With a peel strength of >60N/cm when bonded to EVA (ethylene-vinyl acetate), the backsheet ensures a secure connection, reducing the risk of delamination over time. This is critical for maintaining the electrical and mechanical stability of PV modules.

Thermal aging tests confirm the interface stability of the bonding system, ensuring that the backsheet remains firmly attached to the module even under extreme conditions. This stability is vital for industrial distributed projects where maintenance access may be limited.

The backsheet passes thermal cycling tests without delamination, demonstrating its ability to withstand repeated temperature changes. This feature is particularly important for installations in regions with significant diurnal temperature variations.

Passing the 200kWh/m² UV accelerated aging test, the KPCW1 maintains its structural and functional properties even after prolonged exposure to sunlight. This ensures consistent performance over the module's operational lifespan.

In humid environments, the backsheet retains >85% of its bond strength, preventing moisture ingress and ensuring the longevity of the PV module. This is crucial for coastal areas and regions with high humidity.

Lucky's commitment to quality is reflected in the KPCW1's rigorous production and testing processes. Every batch undergoes comprehensive checks to meet the highest standards.

The Lucky KPCW1 Solar Backsheet is designed for a variety of applications, including:

For more details on solar backsheet materials and types of solar backsheet, visit Lucky's product page.

Baoding Lekai International Ltd. (Lucky) is a leading solar backsheet manufacturer and supplier dedicated to advancing photovoltaic technology. With a focus on R&D and production, the company has established itself as a trusted partner in the renewable energy sector. Lucky's facilities are equipped with state-of-the-art technology to ensure the highest quality standards. For more information, visit Lucky's official website.

| Feature | Specification |

|---|---|

| Material | PVDF Fluoropolymer |

| UV Blocking Rate | >95% |

| Temperature Range | -40°C to 85°C |

| Weather Aging Test | 3000-hour dual 85 (85°C/85% RH) |

| Chemical Resistance | Acids, Alkalis, Solvents, Salt Spray |

| Tensile Strength Retention | >90% after Damp Heat Aging |

| Peel Strength (EVA) | >60N/cm |

| UV Accelerated Aging Test | 200kWh/m² |

| Bond Strength in Humid Environments | >85% |

The Lucky KPCW1 Solar Backsheet stands out as a reliable solution for modern solar energy systems. Its advanced environmental resistance, robust bonding system, and strict quality control make it a preferred choice for solar backsheet manufacturers and suppliers worldwide. As the demand for sustainable energy grows, Lucky's commitment to innovation ensures that the KPCW1 remains at the forefront of photovoltaic technology.

1. National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov/.

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Cost-Saving Strategies for High-Volume DICOM Printing

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.