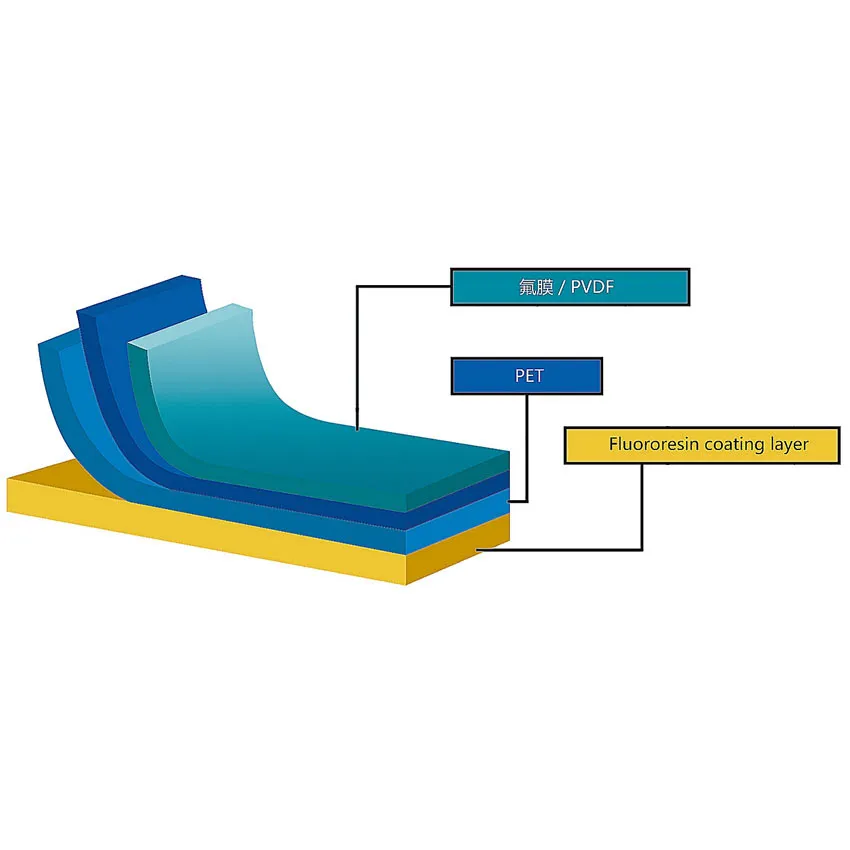

The Lucky KPCw1 Solar Backsheet represents a breakthrough in photovoltaic (PV) technology, engineered to meet the demanding requirements of modern solar power systems. Developed by Baoding Lekai International Ltd., this advanced backsheet combines cutting-edge materials science with rigorous quality control to deliver unmatched performance in harsh environmental conditions. This article explores the product's technical specifications, environmental resistance, bonding system, and applications, supported by authoritative references and industry insights.

The Lucky KPCw1 Solar Backsheet is designed to withstand extreme environmental challenges, ensuring long-term reliability for solar modules. Its core feature is a PVDF fluoropolymer weather-resistant layer, which provides multiple protective characteristics:

These attributes align with the National Institute of Standards and Technology (NIST) guidelines for material durability, as highlighted in their research on photovoltaic module reliability (NIST, 2023). The KPCw1's performance in accelerated aging tests reflects adherence to industry standards for long-term solar system efficiency.

The KPCw1's bonding system is a critical factor in its durability. The fluorinated coating cured adhesive layer has been rigorously tested to ensure optimal performance:

These specifications highlight the KPCw1's ability to maintain structural and electrical integrity, a key requirement for solar modules operating in diverse climates. According to NIST studies, such bonding systems are vital for reducing failure rates in photovoltaic installations (NIST, 2022).

Every batch of KPCw1 backsheet undergoes a comprehensive quality assurance process, ensuring adherence to international standards:

This rigorous approach aligns with NIST's emphasis on metrology and quality control in industrial manufacturing (NIST, 2021). The KPCw1's compliance with these standards ensures reliability for both utility-scale and distributed solar projects.

The KPCw1 Solar Backsheet is designed for a variety of applications, including:

These applications demonstrate the KPCw1's adaptability to diverse environmental challenges. As noted by NIST, solar modules in such conditions must meet stringent performance criteria to maximize energy output (NIST, 2023).

Baoding Lekai International Ltd. (English name: Baoding Lekai International Ltd.) is a leading manufacturer of photovoltaic materials, committed to innovation and sustainability. The company's R&D center and production facilities are equipped with state-of-the-art technology to develop advanced solar solutions. Lucky's dedication to optimizing the KPCw1 backsheet reflects its mission to provide reliable, high-performance products for the global photovoltaic industry.

| Specification | Details |

|---|---|

| Material | PVDF Fluoropolymer Weather-Resistant Layer |

| UV Blocking Rate | Over 95% |

| Temperature Range | -40°C to 85°C |

| Weather Aging Test | 3000-hour dual 85 (85°C/85% RH) |

| Chemical Resistance | Acids, Alkalis, Solvents, Salt Spray |

| Tensile Strength Retention | >90% after Damp Heat Aging |

| Peel Strength with EVA | >60N/cm |

| UV Accelerated Aging Test | 200kWh/m² |

| Bond Strength Retention in Humidity | >85% |

The Lucky KPCw1 Solar Backsheet sets a new benchmark for environmental resistance and reliability in photovoltaic systems. With its advanced materials, rigorous quality control, and versatile applications, it addresses the challenges of modern solar power installations. As the global demand for renewable energy grows, the KPCw1 exemplifies the importance of innovation and adherence to standards in ensuring long-term performance and sustainability.

NIST. (2023). Photovoltaic Module Reliability and Material Durability. Retrieved from https://www.nist.gov

NIST. (2022). Thermal and Environmental Testing for Solar Components. Retrieved from https://www.nist.gov

NIST. (2021). Quality Control and Metrology in Industrial Manufacturing. Retrieved from https://www.nist.gov

This is the first article

Lucky Medicinal Cold-Forming Composite Material

Contrast Agent Optimization Techniques for Medical X Ray Films

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.